DTS

Loudspeaker for home use with three types of dynamic drivers

The hole below the lowest woofer is a port for a bass reflex system.

- Mid-range driver

- Tweeter

- Woofers

A loudspeaker (or loud-speaker or speaker) is an electroacoustic transducer;[1] which converts an electrical audio signal into a corresponding sound.[2] The most widely used type of speaker in the 2010s is the dynamic speaker, invented in 1925 by Edward W. Kellogg and Chester W. Rice. The dynamic speaker operates on the same basic principle as a dynamic microphone, but in reverse, to produce sound from an electrical signal. When an alternating current electrical audio signal is applied to its voice coil, a coil of wire suspended in a circular gap between the poles of a permanent magnet, the coil is forced to move rapidly back and forth due toFaraday's law of induction, which causes adiaphragm (usually conically shaped) attached to the coil to move back and forth, pushing on the air to create sound waves. Besides this most common method, there are several alternative technologies that can be used to convert an electrical signal into sound. The sound source (e.g., a sound recording or a microphone) must be amplified or strengthened with an audio power amplifierbefore the signal is sent to the speaker.

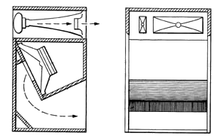

Speakers are typically housed in a speaker enclosure or speaker cabinet which is often a rectangular or square box made of wood or sometimes plastic. The enclosure's materials and design play an important role in the quality of the sound. Where high fidelityreproduction of sound is required, multiple loudspeaker transducers are often mounted in the same enclosure, each reproducing a part of the audible frequency range (picture at right). In this case the individual speakers are referred to as "drivers" and the entire unit is called a loudspeaker. Drivers made for reproducing high audio frequencies are calledtweeters, those for middle frequencies are called mid-range drivers, and those for low frequencies are called woofers. Smaller loudspeakers are found in devices such asradios, televisions, portable audio players,computers, and electronic musical instruments. Larger loudspeaker systems are used for music, sound reinforcement in theatres and concerts, and in public address systems.

Terminology

The term "loudspeaker" may refer to individual transducers (also known as "drivers") or to complete speaker systems consisting of anenclosure including one or more drivers.

To adequately reproduce a wide range of frequencies with even coverage, most loudspeaker systems employ more than one driver, particularly for higher sound pressure level or maximum accuracy. Individual drivers are used to reproduce different frequency ranges. The drivers are named subwoofers(for very low frequencies); woofers (low frequencies); mid-range speakers (middle frequencies); tweeters (high frequencies); and sometimes supertweeters, optimized for the highest audible frequencies. The terms for different speaker drivers differ, depending on the application. In two-way systems there is no mid-range driver, so the task of reproducing the mid-range sounds falls upon the woofer and tweeter. Home stereos use the designation "tweeter" for the high frequency driver, while professional concert systems may designate them as "HF" or "highs". When multiple drivers are used in a system, a "filter network", called a crossover, separates the incoming signal into different frequency ranges and routes them to the appropriate driver. A loudspeaker system withn separate frequency bands is described as "n-way speakers": a two-way system will have a woofer and a tweeter; a three-way system employs a woofer, a mid-range, and a tweeter. Loudspeaker driver of the type pictured are termed "dynamic" (short for electrodynamic) to distinguish them from earlier drivers (i.e.,moving iron speaker), or speakers usingpiezoelectric or electrostatic systems, or any of several other sorts.

History

Johann Philipp Reis installed an electric loudspeaker in his telephone in 1861; it was capable of reproducing clear tones, but also could reproduce muffled speech after a few revisions.[3] Alexander Graham Bell patented his first electric loudspeaker (capable of reproducing intelligible speech) as part of his telephone in 1876, which was followed in 1877 by an improved version from Ernst Siemens. During this time, Thomas Edisonwas issued a British patent for a system using compressed air as an amplifying mechanism for his early cylinder phonographs, but he ultimately settled for the familiar metal horn driven by a membrane attached to the stylus. In 1898, Horace Short patented a design for a loudspeaker driven by compressed air; he then sold the rights to Charles Parsons, who was issued several additional British patents before 1910. A few companies, including theVictor Talking Machine Company and Pathé, produced record players using compressed-air loudspeakers. However, these designs were significantly limited by their poor sound quality and their inability to reproduce sound at low volume. Variants of the system were used for public address applications, and more recently, other variations have been used to test space-equipment resistance to the very loud sound and vibration levels that the launching of rockets produces.

The first experimental moving-coil (also calleddynamic) loudspeaker was invented by Oliver Lodge in 1898.[4] The first practical moving-coil loudspeakers were manufactured by Danish engineer Peter L. Jensen and Edwin Pridham in 1915, in Napa, California.[5] Like previous loudspeakers these used horns to amplify the sound produced by a small diaphragm. Jensen was denied patents. Being unsuccessful in selling their product to telephone companies, in 1915 they changed their target market to radios and public address systems, and named their productMagnavox. Jensen was, for years after the invention of the loudspeaker, a part owner of The Magnavox Company.[6]

The moving-coil principle commonly used today in speakers was patented in 1924 byChester W. Rice and Edward W. Kellogg. The key difference between previous attempts and the patent by Rice and Kellogg is the adjustment of mechanical parameters so that the fundamental resonance of the moving system is below the frequency where the cone's radiation impedance becomes uniform.[7] About this same period, Walter H. Schottky invented the first ribbon loudspeaker together with Dr. Erwin Gerlach.[8]

These first loudspeakers usedelectromagnets, because large, powerfulpermanent magnets were generally not available at a reasonable price. The coil of an electromagnet, called a field coil, was energized by current through a second pair of connections to the driver. This winding usually served a dual role, acting also as a choke coil, filtering the power supply of the amplifier that the loudspeaker was connected to. AC ripple in the current was attenuated by the action of passing through the choke coil. However, AC line frequencies tended to modulate the audio signal going to the voice coil and added to the audible hum.[citation needed] In 1930 Jensenintroduced the first commercial fixed-magnet loudspeaker; however, the large, heavy iron magnets of the day were impractical and field-coil speakers remained predominant until the widespread availability of lightweightAlnico magnets after World War II.

In the 1930s, loudspeaker manufacturers began to combine two and three bandpasses' worth of drivers in order to increase frequency response and sound pressure level.[9] In 1937, the first film industry-standard loudspeaker system, "The Shearer Horn System for Theatres"[10] (a two-way system), was introduced by Metro-Goldwyn-Mayer. It used four 15″ low-frequency drivers, a crossover network set for 375 Hz, and a single multi-cellular horn with two compression drivers providing the high frequencies. John Kenneth Hilliard, James Bullough Lansing, and Douglas Shearer all played roles in creating the system. At the 1939 New York World's Fair, a very large two-way public address system was mounted on a tower at Flushing Meadows. The eight 27″ low-frequency drivers were designed by Rudy Bozak in his role as chief engineer for Cinaudagraph. High-frequency drivers were likely made byWestern Electric.[11]

Altec Lansing introduced the 604, which became their most famous coaxial Duplexdriver, in 1943. It incorporated a high-frequency horn that sent sound through the middle of a 15-inch woofer for near-point-source performance.[12] Altec's "Voice of the Theatre" loudspeaker system arrived in the marketplace in 1945, offering better coherence and clarity at the high output levels necessary in movie theaters.[13] The Academy of Motion Picture Arts and Sciences immediately began testing its sonic characteristics; they made it the film houseindustry standard in 1955.[14]

In 1954, Edgar Villchur developed the acoustic suspension principle of loudspeaker design inCambridge, Massachusetts. This allowed for better bass response than previously from drivers mounted in smaller cabinets which was important during the transition to stereo recording and reproduction. He and his partner Henry Kloss formed the Acoustic Research company to manufacture and market speaker systems using this principle. Subsequently, continuous developments in enclosure design and materials led to significant audible improvements.[citation needed]The most notable improvements to date in modern dynamic drivers, and the loudspeakers that employ them, are improvements in cone materials, the introduction of higher-temperature adhesives, improved permanent magnet materials, improved measurement techniques, computer-aided design, and finite element analysis. At low frequencies, the application of electrical network theory to the acoustic performance allowed by various enclosure designs (initially by Thiele, and later by Small) has been very important at the design level.[citation needed]

Driver design: dynamic loudspeakers

The most common type of driver, commonly called a dynamic loudspeaker, uses a lightweight diaphragm, or cone, connected to a rigid basket, or frame, via a flexible suspension, commonly called a spider, that constrains a voice coil to move axially through a cylindrical magnetic gap. When an electrical signal is applied to the voice coil, a magnetic field is created by the electric current in the voice coil, making it a variable electromagnet. The coil and the driver's magnetic system interact, generating a mechanical force that causes the coil (and thus, the attached cone) to move back and forth, accelerating and reproducing sound under the control of the applied electrical signal coming from theamplifier. The following is a description of the individual components of this type of loudspeaker.

The diaphragm is usually manufactured with a cone- or dome-shaped profile. A variety of different materials may be used, but the most common are paper, plastic, and metal. The ideal material would 1) be rigid, to prevent uncontrolled cone motions; 2) have low mass, to minimize starting force requirements and energy storage issues; 3) be well damped, to reduce vibrations continuing after the signal has stopped with little or no audible ringing due to its resonance frequency as determined by its usage. In practice, all three of these criteria cannot be met simultaneously using existing materials; thus, driver design involvestrade-offs. For example, paper is light and typically well damped, but is not stiff; metal may be stiff and light, but it usually has poor damping; plastic can be light, but typically, the stiffer it is made, the poorer the damping. As a result, many cones are made of some sort of composite material. For example, a cone might be made of cellulose paper, into which some carbon fiber, Kevlar, glass, hemp orbamboo fibers have been added; or it might use a honeycomb sandwich construction; or a coating might be applied to it so as to provide additional stiffening or damping.

The chassis, frame, or basket, is designed to be rigid, avoiding deformation that could change critical alignments with the magnet gap, perhaps causing the voice coil to rub against the sides of the gap. Chassis are typically cast from aluminum alloy, orstamped from thin steel sheet, though in some drivers with large magnets cast chassis are preferable as sheet metal can easily be warped in whenever the loudspeaker is subjected to rough handling.[15] Other materials such as molded plastic and damped plastic compound baskets are becoming common, especially for inexpensive, low-mass drivers. Metallic chassis can play an important role in conducting heat away from the voice coil; heating during operation changes resistance, causes physical dimensional changes, and if extreme, may even demagnetize permanent magnets.

The suspension system keeps the coil centered in the gap and provides a restoring (centering) force that returns the cone to a neutral position after moving. A typical suspension system consists of two parts: thespider, which connects the diaphragm or voice coil to the frame and provides the majority of the restoring force, and thesurround, which helps center the coil/cone assembly and allows free pistonic motion aligned with the magnetic gap. The spider is usually made of a corrugated fabric disk, impregnated with a stiffening resin. The name comes from the shape of early suspensions, which were two concentric rings of Bakelitematerial, joined by six or eight curved "legs." Variations of this topology included the addition of a felt disc to provide a barrier to particles that might otherwise cause the voice coil to rub. The German firm Rulik still offers drivers with uncommon spiders made of wood.

The cone surround can be rubber or polyesterfoam, or a ring of corrugated, resin coated fabric; it is attached to both the outer diaphragm circumference and to the frame. These diverse surround materials, their shape and treatment can dramatically affect the acoustic output of a driver; each implementation having advantages and disadvantages. Polyester foam, for example, is lightweight and economical, though usually leaking air to some degree, but is degraded by exposure to ozone, UV light, humidity and elevated temperatures, significantly limiting useful life with adequate performance.

The wire in a voice coil is usually made ofcopper, though aluminum—and, rarely, silver—may be used. The advantage of aluminum is its light weight, which reduces the moving mass compared to copper. This raises the resonant frequency of the speaker and increases its efficiency. A disadvantage of aluminum is that it is not easily soldered, and so connections are instead often crimped together and sealed. These connections must be made well or they may fail in an intense environment of mechanical vibration. Voice-coil wire cross sections can be circular, rectangular, or hexagonal, giving varying amounts of wire volume coverage in the magnetic gap space. The coil is oriented co-axially inside the gap; it moves back and forth within a small circular volume (a hole, slot, or groove) in the magnetic structure. The gap establishes a concentrated magnetic field between the two poles of a permanent magnet; the outside of the gap being one pole, and the center post (called the pole piece) being the other. The pole piece and backplate are often a single piece, called the poleplate or yoke.

Modern driver magnets are almost always permanent and made of ceramic, ferrite,Alnico, or, more recently, rare earth such asneodymium and samarium cobalt. Electrodynamic drivers were often used in musical instrument amplifier/speaker cabinets well into the 1950s; there were economic savings in those using tube amplifiers as the field coil could, and usually did, do double duty as a power supply choke. A trend in design — due to increases in transportation costs and a desire for smaller, lighter devices (as in many home theater multi-speaker installations) — is the use of the last instead of heavier ferrite types. Very few manufacturers still produce electrodynamic loudspeakers with electrically powered field coils, as was common in the earliest designs; one of the last is a French firm. When high field-strength permanent magnets became available after WWII, Alnico, an alloy of aluminum, nickel, and cobalt became popular, since it dispensed with the problems of field-coil drivers. Alnico was used almost exclusively until about 1980, despite the embarrassing problem of Alnico magnets being partially degaussed (i.e., demagnetized) by accidental 'pops' or 'clicks' caused by loose connections, especially if used with a high-power amplifier. The damage can be reversed by "recharging" the magnet, but this requires uncommon specialist equipment and knowledge.

After 1980, most (but not quite all) driver manufacturers switched from Alnico to ferrite magnets, which are made from a mix of ceramic clay and fine particles of barium or strontium ferrite. Although the energy per kilogram of these ceramic magnets is lower than Alnico, it is substantially less expensive, allowing designers to use larger yet more economical magnets to achieve a given performance.

The size and type of magnet and details of the magnetic circuit differ, depending on design goals. For instance, the shape of the pole piece affects the magnetic interaction between the voice coil and the magnetic field, and is sometimes used to modify a driver's behavior. A "shorting ring", or Faraday loop, may be included as a thin copper cap fitted over the pole tip or as a heavy ring situated within the magnet-pole cavity. The benefits of this complication is reduced impedance at high frequencies, providing extended treble output, reduced harmonic distortion, and a reduction in the inductance modulation that typically accompanies large voice coil excursions. On the other hand, the copper cap requires a wider voice-coil gap, with increased magnetic reluctance; this reduces available flux, requiring a larger magnet for equivalent performance.

Driver design—including the particular way two or more drivers are combined in an enclosure to make a speaker system—is both an art, involving subjective perceptions oftimbre and sound quality and a science, involving measurements and experiments.[16][17][18] Adjusting a design to improve performance is done using a combination of magnetic, acoustic, mechanical, electrical, and material science theory, and tracked with high precision measurements and the observations of experienced listeners. A few of the issues speaker and driver designers must confront are distortion, radiation lobing, phase effects, off-axis response, and crossover artifacts. Designers can use an anechoic chamber to ensure the speaker can be measured independently of room effects, or any of several electronic techniques that, to some extent, substitute for such chambers. Some developers eschew anechoic chambers in favor of specific standardized room setups intended to simulate real-life listening conditions.

Fabrication of finished loudspeaker systems has become segmented, depending largely on price, shipping costs, and weight limitations. High-end speaker systems, which are typically heavier (and often larger) than economic shipping allows outside local regions, are usually made in their target market region and can cost $140,000 or more per pair.[19]Economical mass market speaker systems and drivers available for much lower costs may be manufactured in China or other low-cost manufacturing locations.

Driver types

A four-way, high fidelity loudspeaker system. Each of the four drivers outputs a different frequency range; the fifth aperture at the bottom is abass reflex port.

Individual electrodynamic drivers provide their best performance within a limited frequency range. Multiple drivers (e.g., subwoofers, woofers, mid-range drivers, and tweeters) are generally combined into a complete loudspeaker system to provide performance beyond that constraint. The three most commonly used sound radiation systems are the cone, dome and horn type drivers.

Full-range drivers

A full-range driver is a speaker designed to be used alone to reproduce an audio channel without the help of other drivers, and therefore must cover the entire audio frequency range. These drivers are small, typically 3 to 8 inches (7.6 to 20.3 cm) in diameter to permit reasonable high frequency response, and carefully designed to give low-distortion output at low frequencies, though with reduced maximum output level. Full-range (or more accurately, wide-range) drivers are most commonly heard in public address systems, in televisions (although some models are suitable for hi-fi listening), small radios, intercoms, some computer speakers, etc. In hi-fi speaker systems, the use of wide-range drive units can avoid undesirable interactions between multiple drivers caused by non-coincident driver location or crossover network issues. Fans of wide-range driver hi-fi speaker systems claim a coherence of sound due to the single source and a resulting lack of interference, and likely also to the lack of crossover components. Detractors typically cite wide-range drivers' limited frequency response and modest output abilities (most especially at low frequencies), together with their requirement for large, elaborate, expensive enclosures—such as transmission lines, quarter wave resonators or horns—to approach optimum performance. With the advent of neodymium drivers, low cost quarter wave transmission lines are made possible and are increasingly made availably commercially.[20][21]

Full-range drivers often employ an additional cone called a whizzer: a small, light cone attached to the joint between the voice coil and the primary cone. The whizzer cone extends the high-frequency response of the driver and broadens its high frequency directivity, which would otherwise be greatly narrowed due to the outer diameter cone material failing to keep up with the central voice coil at higher frequencies. The main cone in a whizzer design is manufactured so as to flex more in the outer diameter than in the center. The result is that the main cone delivers low frequencies and the whizzer cone contributes most of the higher frequencies. Since the whizzer cone is smaller than the main diaphragm, output dispersion at high frequencies is improved relative to an equivalent single larger diaphragm.

Limited-range drivers, also used alone, are typically found in computers, toys, and clock radios. These drivers are less elaborate and less expensive than wide-range drivers, and they may be severely compromised to fit into very small mounting locations. In these applications, sound quality is a low priority. The human ear is remarkably tolerant of poor sound quality, and the distortion inherent in limited-range drivers may enhance their output at high frequencies, increasing clarity when listening to spoken word material.

Subwoofer

A subwoofer is a woofer driver used only for the lowest-pitched part of the audio spectrum: typically below 200 Hz for consumer systems,[22] below 100 Hz for professional live sound,[23] and below 80 Hz in THX-approved systems.[24] Because the intended range of frequencies is limited, subwoofer system design is usually simpler in many respects than for conventional loudspeakers, often consisting of a single driver enclosed in a suitable box or enclosure. Since sound in this frequency range can easily bend around corners by diffraction, the speaker aperture does not have to face the audience, and subwoofers can be mounted in the bottom of the enclosure, facing the floor. This is eased by the limitations of human hearing at low frequencies; such sounds cannot be located in space, due to their large wavelengths compared to higher frequencies which produce differential effects in the ears due to shadowing by the head, and diffraction around it, both of which we rely upon for localization clues.

To accurately reproduce very low bass notes without unwanted resonances (typically from cabinet panels), subwoofer systems must be solidly constructed and properly braced to avoid unwanted sounds of cabinet vibrations. As a result, good subwoofers are typically quite heavy. Many subwoofer systems include integrated power amplifiers and electronicsubsonic (sub)-filters, with additional controls relevant to low-frequency reproduction (e.g., a crossover knob and a phase switch). These variants are known as "active" or "powered" subwoofers, with the former including a power amplifier.[25] In contrast, "passive" subwoofers require external amplification.

In typical installations, subwoofers are physically separated from the rest of the speaker cabinets. Because of propagation delay, their output may be somewhat out of phase from another subwoofer (on another channel) or slightly out of phase with the rest of the sound. Consequently, a subwoofer's power amp often has a phase-delay adjustment (approximately 1 ms of delay is required for each additional foot of separation from the listener) which may improve performance of the system as a whole at subwoofer frequencies (and perhaps an octave or so above the crossover point). However, the influence of room resonances (sometimes called standing waves) is typically so large that such issues are secondary in practice. Subwoofers are widely used in large concert and mid-sized venuesound reinforcement systems. Subwoofer cabinets are often built with a bass reflex port (i.e., a hole cut into the cabinet with a tube attached to it), a design feature which if properly engineered improves bass performance and increases efficiency.

Woofer

A woofer is a driver that reproduces low frequencies. The driver works with the characteristics of the enclosure to produce suitable low frequencies (see speaker enclosure for some of the design choices available). Indeed, both are so closely connected that they must be considered together in use. Only at design time do the separate properties of enclosure and woofer matter individually. Some loudspeaker systems use a woofer for the lowest frequencies, sometimes well enough that a subwoofer is not needed. Additionally, some loudspeakers use the woofer to handle middle frequencies, eliminating the mid-range driver. This can be accomplished with the selection of a tweeter that can work low enough that, combined with a woofer that responds high enough, the two drivers add coherently in the middle frequencies.

Mid-range driver

A mid-range speaker is a loudspeaker driver that reproduces a band of frequencies generally between 1–6 kHz, otherwise known as the 'mid' frequencies (between the woofer and tweeter). Mid-range driver diaphragms can be made of paper or composite materials, and can be direct radiation drivers (rather like smaller woofers) or they can be compression drivers (rather like some tweeter designs). If the mid-range driver is a direct radiator, it can be mounted on the front baffle of a loudspeaker enclosure, or, if a compression driver, mounted at the throat of a horn for added output level and control of radiation pattern.

Tweeter

Exploded view of a dome tweeter.

A tweeter is a high-frequency driver that reproduces the highest frequencies in a speaker system. A major problem in tweeter design is achieving wide angular sound coverage (off-axis response), since high frequency sound tends to leave the speaker in narrow beams. Soft-dome tweeters are widely found in home stereo systems, and horn-loaded compression drivers are common in professional sound reinforcement. Ribbon tweeters have gained popularity in recent years, as the output power of some designs has been increased to levels useful for professional sound reinforcement, and their output pattern is wide in the horizontal plane, a pattern that has convenient applications in concert sound.[26]

Coaxial drivers

A coaxial driver is a loudspeaker driver with two or several combined concentric drivers. Coaxial drivers have been produced by many companies, such as Altec, Tannoy, Pioneer,KEF, SEAS, B&C Speakers, BMS, Cabasse andGenelec.[27]

System design

Crossover

Used in multi-driver speaker systems, the crossover is an assembly of filters that separate the input signal into different frequency ranges (i.e. "bands"), according to the requirements of each driver. Hence the drivers receive power only at their operating frequency (the sound frequency range they were designed for), thereby reducing distortion in the drivers and interference between them. The ideal characteristics of a crossover may include perfect out-of-band attenuation at the output of each filter, no amplitude variation ("ripple") within each passband, no phase delay between overlapping frequency bands, to name just a few.

Crossovers can be passive or active. Apassive crossover is an electronic circuit that uses a combination of one or more resistors, inductors, or non-polar capacitors. These components are combined to form a filter network and are most often placed between the full frequency-range power amplifier and the loudspeaker drivers to divide the amplifier's signal into the necessary frequency bands before being delivered to the individual drivers. Passive crossover circuits need no external power beyond the audio signal itself, but have some disadvantages: they may require larger inductors and capacitors due to power handling requirements (being driven by the amplifier), limited component availability to optimize the crossover's characteristics at such power levels, etc. Unlike active crossovers which include a built-in amplifier, passive crossovers have an inherent attenuation within the passband, typically leading to a reduction indamping factor before the voice coil [28] Anactive crossover is an electronic filter circuit that divides the signal into individual frequency bands before power amplification, thus requiring at least one power amplifier for each bandpass.[28] Passive filtering may also be used in this way before power amplification, but it is an uncommon solution, being less flexible than active filtering. Any technique that uses crossover filtering followed by amplification is commonly known as bi-amping, tri-amping, quad-amping, and so on, depending on the minimum number of amplifier channels.[29]

Some loudspeaker designs use a combination of passive and active crossover filtering, such as a passive crossover between the mid- and high-frequency drivers and an active crossover between the low-frequency driver and the combined mid- and high frequencies.[30][31]

Passive crossovers are commonly installed inside speaker boxes and are by far the most usual type of crossover for home and low-power use. In car audio systems, passive crossovers may be in a separate box, necessary to accommodate the size of the components used. Passive crossovers may be simple for low-order filtering, or complex to allow steep slopes such as 18 or 24 dB per octave. Passive crossovers can also be designed to compensate for undesired characteristics of driver, horn, or enclosure resonances,[32] and can be tricky to implement, due to component interaction. Passive crossovers, like the driver units that they feed, have power handling limits, have insertion losses (10% is often claimed), and change the load seen by the amplifier. The changes are matters of concern for many in the hi-fi world.[32] When high output levels are required, active crossovers may be preferable. Active crossovers may be simple circuits that emulate the response of a passive network, or may be more complex, allowing extensive audio adjustments. Some active crossovers, usually digital loudspeaker management systems, may include electronics and controls for precise alignment of phase and time between frequency bands, equalization,dynamic range compression and limiting) control.[28]

Enclosures

Most loudspeaker systems consist of drivers mounted in an enclosure, or cabinet. The role of the enclosure is to prevent sound waves emanating from the back of a driver from interfering destructively with those from the front. The sound waves emitted from the back are 180° out of phase with those emitted forward, so without an enclosure they typically cause cancellations which significantly degrade the level and quality of sound at low frequencies.

The simplest driver mount is a flat panel (i.e., baffle) with the drivers mounted in holes in it. However, in this approach, sound frequencies with a wavelength longer than the baffle dimensions are canceled out, because the antiphase radiation from the rear of the cone interferes with the radiation from the front. With an infinitely large panel, this interference could be entirely prevented. A sufficiently large sealed box can approach this behavior.[33][34]

Since panels of infinite dimensions are impossible, most enclosures function by containing the rear radiation from the moving diaphragm. A sealed enclosure prevents transmission of the sound emitted from the rear of the loudspeaker by confining the sound in a rigid and airtight box. Techniques used to reduce transmission of sound through the walls of the cabinet include thicker cabinet walls, lossy wall material, internal bracing, curved cabinet walls—or more rarely,visco-elastic materials (e.g., mineral-loadedbitumen) or thin lead sheeting applied to the interior enclosure walls.

However, a rigid enclosure reflects sound internally, which can then be transmitted back through the loudspeaker diaphragm—again resulting in degradation of sound quality. This can be reduced by internal absorption using absorptive materials (often called "damping"), such as glass wool, wool, or synthetic fiber batting, within the enclosure. The internal shape of the enclosure can also be designed to reduce this by reflecting sounds away from the loudspeaker diaphragm, where they may then be absorbed.

Other enclosure types alter the rear sound radiation so it can add constructively to the output from the front of the cone. Designs that do this (including bass reflex, passive radiator, transmission line, etc.) are often used to extend the effective low-frequency response and increase low-frequency output of the driver.

To make the transition between drivers as seamless as possible, system designers have attempted to time-align (or phase adjust) the drivers by moving one or more driver mounting locations forward or back so that the acoustic center of each driver is in the same vertical plane. This may also involve tilting the face speaker back, providing a separate enclosure mounting for each driver, or (less commonly) using electronic techniques to achieve the same effect. These attempts have resulted in some unusual cabinet designs.

The speaker mounting scheme (including cabinets) can also cause diffraction, resulting in peaks and dips in the frequency response. The problem is usually greatest at higher frequencies, where wavelengths are similar to, or smaller than, cabinet dimensions. The effect can be minimized by rounding the front edges of the cabinet, curving the cabinet itself, using a smaller or narrower enclosure, choosing a strategic driver arrangement, using absorptive material around a driver, or some combination of these and other schemes.

Horn loudspeakers

Horn loudspeakers are the oldest form of loudspeaker system. The use of horns as voice-amplifying megaphones dates at least to the 17th century,[35] and horns were used in mechanical gramophones as early as 1857. Horn loudspeakers use a shaped waveguide in front of or behind the driver to increase the directivity of the loudspeaker and to transform a small diameter, high pressure condition at the driver cone surface to a large diameter, low pressure condition at the mouth of the horn. This improves the acoustic—electro/mechanical impedance match between the driver and ambient air, increasing efficiency, and focusing the sound over a narrower area.

The size of the throat, mouth, the length of the horn, as well as the area expansion rate along it must be carefully chosen to match the drive to properly provide this transforming function over a range of frequencies (every horn performs poorly outside its acoustic limits, at both high and low frequencies). The length and cross-sectional mouth area required to create a bass or sub-bass horn require a horn many feet long. 'Folded' horns can reduce the total size, but compel designers to make compromises and accept increased complication such as cost and construction. Some horn designs not only fold the low frequency horn, but use the walls in a room corner as an extension of the horn mouth. In the late 1940s, horns whose mouths took up much of a room wall were not unknown amongst hi-fi fans. Room sized installations became much less acceptable when two or more were required.

A horn loaded speaker can have a sensitivity as high as 110 dB at 2.83 volts (1 watt at 8 ohms) at 1 meter. This is a hundredfold increase in output compared to a speaker rated at 90 dB sensitivity, and is invaluable in applications where high sound levels are required or amplifier power is limited.

Wiring connections

Two-way binding posts on a loudspeaker, connected using banana plugs.

Most home hi-fi loudspeakers use two wiring points to connect to the source of the signal (for example, to the audio amplifier orreceiver). To accept the wire connection, the loudspeaker enclosure may have binding posts, spring clips, or a panel-mount jack. If the wires for a pair of speakers are not connected with respect to the properelectrical polarity (the + and − connections on the speaker and amplifier should be connected + to + and − to −; speaker cable is almost always marked so that one conductor of a pair can be distinguished from the other, even if it has run under or behind things in its run from amplifier to speaker location), the loudspeakers are said to be "out of phase" or more properly "out of polarity".[36][37] Given identical signals, motion in one cone is in the opposite direction of the other. This typically causes monophonic material in a stereo recording to be canceled out, reduced in level, and made more difficult to localize, all due to destructive interference of the sound waves. The cancellation effect is most noticeable at frequencies where the loudspeakers are separated by a quarter wavelength or less; low frequencies are affected the most. This type of miswiring error does not damage speakers, but is not optimal for listening.[38][39]

With sound reinforcement system, PA systemand instrument amplifier speaker enclosures, cables and some type of jack or connector are typically used. Lower- and mid-priced sound system and instrument speaker cabinets often use 1/4" speaker cable jacks. Higher-priced and higher powered sound system cabinets and instrument speaker cabinets often use Speakon connectors. Speakon connectors are considered to be safer for high wattage amplifiers, because the connector is designed so that human users cannot touch the connectors.

Wireless speakers

Wireless speakers are very similar to traditional (wired) loudspeakers, but they receive audio signals using radio frequency (RF) waves rather than over audio cables. There is normally an amplifier integrated in the speaker's cabinet because the RF waves alone are not enough to drive the speaker. This integration of amplifier and loudspeaker is known as an active loudspeaker. Manufacturers of these loudspeakers design them to be as lightweight as possible while producing the maximum amount of audio output efficiency.

Wireless speakers still need power, so require a nearby AC power outlet, or possibly batteries. Only the wire to the amplifier is eliminated.

Comments

Post a Comment