Glass

The joining of two tubes made oflead glass during glass welding

Glass is a non-crystalline amorphous solidthat is often transparent and has widespread practical, technological, and decorative usage in, for example, window panes, tableware, andoptoelectronics. The most familiar, and historically the oldest, types of glass are "silicate glasses" based on the chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. The termglass, in popular usage, is often used to refer only to this type of material, which is familiar from use as window glass and in glass bottles. Of the many silica-based glasses that exist, ordinary glazing and container glass is formed from a specific type called soda-lime glass, composed of approximately 75% silicon dioxide (SiO2), sodium oxide (Na2O) fromsodium carbonate (Na2CO3), calcium oxide, also called lime (CaO), and several minor additives.

Many applications of silicate glasses derive from their optical transparency, giving rise to their primary use as window panes. Glass willtransmit, reflect and refract light; these qualities can be enhanced by cutting and polishing to make optical lenses, prisms, fine glassware, and optical fibers for high speed data transmission by light. Glass can be coloured by adding metallic salts, and can also be painted and printed with vitreous enamels. These qualities have led to the extensive use of glass in the manufacture ofart objects and in particular, stained glass windows. Although brittle, silicate glass is extremely durable, and many examples of glass fragments exist from early glass-making cultures. Because glass can be formed or moulded into any shape, it has been traditionally used for vessels: bowls,vases, bottles, jars and drinking glasses. In its most solid forms it has also been used forpaperweights, marbles, and beads. When extruded as glass fiber and matted as glass wool in a way to trap air, it becomes a thermal insulating material, and when these glass fibers are embedded into an organic polymerplastic, they are a key structural reinforcement part of the composite material fiberglass. Some objects historically were so commonly made of silicate glass that they are simply called by the name of the material, such as drinking glasses and eyeglasses.

Scientifically, the term "glass" is often defined in a broader sense, encompassing every solid that possesses a non-crystalline (that is, amorphous) structure at the atomic scale and that exhibits a glass transition when heated towards the liquid state. Porcelains and many polymer thermoplastics familiar from everyday use are glasses. These sorts of glasses can be made of quite different kinds of materials than silica: metallic alloys, ionic melts, aqueous solutions, molecular liquids, and polymers. For many applications, likeglass bottles or eyewear, polymer glasses (acrylic glass, polycarbonate or polyethylene terephthalate) are a lighter alternative than traditional glass.

Silicate glass

Ingredients

Silica (SiO2) is a common fundamental constituent of glass.[1] In nature, vitrificationof quartz occurs when lightning strikes sand, forming hollow, branching rootlike structures called fulgurites.[2]

Fused quartz is a glass made from chemically-pure silica. It has excellent resistance to thermal shock, being able to survive immersion in water while red hot. However, its high melting temperature (1723 °C) and viscosity make it difficult to work with.[3] Normally, other substances are added to simplify processing. One is sodium carbonate (Na2CO3, "soda"), which lowers the glass-transition temperature. The soda makes the glass water-soluble, which is usually undesirable, so lime (CaO, calcium oxide, generally obtained from limestone), somemagnesium oxide (MgO) and aluminium oxide(Al2O3) are added to provide for a better chemical durability. The resulting glass contains about 70 to 74% silica by weight and is called a soda-lime glass.[4] Soda-lime glasses account for about 90% of manufactured glass.[5][6]

Most common glass contains other ingredients to change its properties. Lead glass or flint glass is more "brilliant" because the increased refractive index causes noticeably more specular reflection and increased optical dispersion. Adding bariumalso increases the refractive index. Thorium oxide gives glass a high refractive index and low dispersion and was formerly used in producing high-quality lenses, but due to itsradioactivity has been replaced by lanthanum oxide in modern eyeglasses.[7] Iron can be incorporated into glass to absorb infraredradiation, for example in heat-absorbing filters for movie projectors, while cerium(IV) oxidecan be used for glass that absorbs ultravioletwavelengths.[8]

The following is a list of the more common types of silicate glasses and their ingredients, properties, and applications:

- Fused quartz,[9] also called fused-silica glass,[10] vitreous-silica glass: silica (SiO2) in vitreous, or glass, form (i.e., its molecules are disordered and random, without crystalline structure). It has very low thermal expansion, is very hard, and resists high temperatures (1000–1500 °C). It is also the most resistant against weathering (caused in other glasses by alkali ions leaching out of the glass, while staining it). Fused quartz is used for high-temperature applications such as furnace tubes, lighting tubes, melting crucibles, etc.[11]

- Soda-lime-silica glass, window glass:[12]silica + sodium oxide (Na2O) + lime (CaO) + magnesia (MgO) + alumina (Al2O3).[13][14] Is transparent,[15] easily formed and most suitable for window glass (see flat glass).[16] It has a high thermal expansion and poor resistance to heat[15] (500–600 °C).[11] It is used for windows, some low-temperature incandescent light bulbs, and tableware.[17] Container glass is a soda-lime glass that is a slight variation on flat glass, which uses more alumina and calcium, and less sodium and magnesium, which are more water-soluble. This makes it less susceptible to water erosion.

- Sodium borosilicate glass, Pyrex: silica +boron trioxide (B2O3) + soda (Na2O) + alumina (Al2O3).[18] Stands heat expansion much better than window glass.[10] Used for chemical glassware, cooking glass, carhead lamps, etc. Borosilicate glasses (e.g.Pyrex, Duran) have as main constituents silica and boron trioxide. They have fairly low coefficients of thermal expansion(7740 Pyrex CTE is 3.25×10−6/°C[19] as compared to about 9×10−6/°C for a typical soda-lime glass[20]), making them more dimensionally stable. The lower coefficient of thermal expansion (CTE) also makes them less subject to stress caused bythermal expansion, thus less vulnerable tocracking from thermal shock. They are commonly used for reagent bottles, optical components and household cookware.

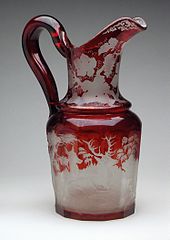

- Lead-oxide glass, crystal glass,[11] lead glass:[21] silica + lead oxide (PbO) + potassium oxide (K2O) + soda (Na2O) + zinc oxide (ZnO) + alumina. Because of its high density (resulting in a high electron density), it has a high refractive index, making the look of glassware more brilliant[22] (called "crystal", though of course it is a glass and not a crystal). It also has a high elasticity, making glassware "ring". It is also more workable in the factory, but cannot stand heating very well.[11] This kind of glass is also more fragile than other glasses[23] and is easier to cut.[22]

- Aluminosilicate glass: silica + alumina + lime + magnesia[24] + barium oxide (BaO)[11]+ boric oxide (B2O3).[24] Extensively used forfiberglass,[24] used for making glass-reinforced plastics (boats, fishing rods, etc.) and for halogen bulb glass.[11]Aluminosilicate glasses are also resistant to weathering and water erosion.[25]

- Germanium-oxide glass: alumina +germanium dioxide (GeO2). Extremely clear glass, used for fiber-optic waveguides in communication networks.[26] Light loses only 5% of its intensity through 1 km of glass fiber.[11]

Another common glass ingredient is crushed alkali glass or 'cullet' ready for recycled glass. The recycled glass saves on raw materials and energy. Impurities in the cullet can lead to product and equipment failure. Fining agents such as sodium sulfate, sodium chloride, orantimony oxide may be added to reduce the number of air bubbles in the glass mixture.[4]Glass batch calculation is the method by which the correct raw material mixture is determined to achieve the desired glass composition.[27]

Physical properties

Optical properties

Glass is in widespread use largely due to the production of glass compositions that are transparent to visible light. In contrast,polycrystalline materials do not generally transmit visible light.[28] The individual crystallites may be transparent, but their facets (grain boundaries) reflect or scatter light resulting in diffuse reflection. Glass does not contain the internal subdivisions associated with grain boundaries in polycrystals and hence does not scatter light in the same manner as a polycrystalline material. The surface of a glass is often smooth since during glass formation the molecules of the supercooled liquid are not forced to dispose in rigid crystal geometries and can follow surface tension, which imposes a microscopically smooth surface. These properties, which give glass its clearness, can be retained even if glass is partially light-absorbing—i.e., colored.[29]

Glass has the ability to refract, reflect, and transmit light following geometrical optics,[30]without scattering it (due to the absence of grain boundaries).[31] It is used in the manufacture of lenses and windows.[32]Common glass has a refraction index around 1.5.[33] This may be modified by adding low-density materials[34] such as boron, which lowers the index of refraction (see crown glass),[35] or increased (to as much as 1.8) with high-density materials such as (classically) lead oxide (see flint glass andlead glass), or in modern uses, less toxic oxides of zirconium, titanium, or barium. These high-index glasses (inaccurately known as "crystal" when used in glass vessels) cause more chromatic dispersion of light, and are prized for their diamond-like optical properties.

According to Fresnel equations, thereflectivity of a sheet of glass is about 4% per surface (at normal incidence in air),[36] and thetransmissivity of one element (two surfaces) is about 90%.[37] Glass with high germaniumoxide content also finds application inoptoelectronics[38]—e.g., for light-transmittingoptical fibers.[39]

Other properties

In the process of manufacture, silicate glass can be poured, formed, extruded and molded into forms ranging from flat sheets to highly intricate shapes.[40] The finished product is brittle[41] and will fracture, unless laminated or specially treated,[42] but is extremely durable under most conditions.[43] It erodes very slowly[44] and can mostly withstand the action of water.[45] It is mostly resistant to chemical attack,[46] does not react with foods, and is an ideal material for the manufacture of containers for foodstuffs and most chemicals.[47] Glass is also a fairly inert substance.[48]

Corrosion

Although glass is generally corrosion-resistant[49] and more corrosion resistant than other materials, it still can be corroded.[43] The materials that make up a particular glass composition has an effect on how quickly the glass corrodes.[46] A glass containing a high proportion of alkalis[50] or alkali earths is less corrosion-resistant than other kinds of glasses.[51]

Glass flakes have applications as anti-corrosive coating.[52]

Strength

Glass typically has a tensile strength of 7megapascals (1,000 psi)[53], however theoretically it can have a strength of 17 gigapascals (2,500,000 psi) due to glass's strong chemical bonds. Several factors such as imperfections like scratches and bubbles[54] and the glass's chemical composition impact the tensile strength of glass.[55] Several processes such astoughening can increase the strength of glass.[56]

Contemporary production

Following the glass batch preparation and mixing, the raw materials are transported to the furnace. Soda-lime glass for mass production is melted in gas fired units. Smaller scale furnaces for specialty glasses include electric melters, pot furnaces, and day tanks.[4] After melting, homogenization andrefining (removal of bubbles), the glass isformed. Flat glass for windows and similar applications is formed by the float glassprocess, developed between 1953 and 1957 by Sir Alastair Pilkington and Kenneth Bickerstaff of the UK's Pilkington Brothers, who created a continuous ribbon of glass using a molten tin bath on which the molten glass flows unhindered under the influence of gravity. The top surface of the glass is subjected to nitrogen under pressure to obtain a polished finish.[57] Container glass for common bottles and jars is formed byblowing and pressing methods.[58] This glass is often slightly modified chemically (with more alumina and calcium oxide) for greater water resistance. Further glass forming techniques are summarized in the table Glass forming techniques.

Once the desired form is obtained, glass is usually annealed for the removal of stresses and to increase the glass's hardness and durability.[59] Surface treatments, coatings orlamination may follow to improve the chemical durability (glass container coatings,glass container internal treatment), strength (toughened glass, bulletproof glass,windshields[60]), or optical properties (insulated glazing, anti-reflective coating).[citation needed]

Color

Color in glass may be obtained by addition of electrically charged ions (or color centers) that are homogeneously distributed, and by precipitation of finely dispersed particles (such as in photochromic glasses).[61]Ordinary soda-lime glass appears colorless to the naked eye when it is thin, although iron(II) oxide (FeO) impurities of up to 0.1 wt%[62]produce a green tint, which can be viewed in thick pieces or with the aid of scientific instruments. Further FeO and chromium(III) oxide (Cr2O3) additions may be used for the production of green bottles. Sulfur, together with carbon and iron salts, is used to form iron polysulfides and produce amber glass ranging from yellowish to almost black.[63] A glass melt can also acquire an amber color from a reducing combustion atmosphere.[64]Manganese dioxide can be added in small amounts to remove the green tint given by iron(II) oxide. Art glass and studio glasspieces are colored using closely guarded recipes that involve specific combinations of metal oxides, melting temperatures and "cook" times. Most colored glass used in the art market is manufactured in volume by vendors who serve this market, although there are some glassmakers with the ability to make their own color from raw materials.

History of silicate glass

Roman cage cup from the 4th century CE

Studio glass. Multiple colors within a single object increase the difficulty of production, as glasses of different colors have different chemical and physical properties when molten.

Naturally occurring glass, especially thevolcanic glass obsidian, was used by manyStone Age societies across the globe for the production of sharp cutting tools and, due to its limited source areas, was extensively traded. But in general, archaeological evidence suggests that the first true glass was made in coastal north Syria,Mesopotamia or ancient Egypt.[65] The earliest known glass objects, of the mid third millennium BCE, were beads, perhaps initially created as accidental by-products of metal-working (slags) or during the production offaience, a pre-glass vitreous material made by a process similar to glazing.[66]

Glass remained a luxury material, and thedisasters that overtook Late Bronze Age civilizations seem to have brought glass-making to a halt. Indigenous development of glass technology in South Asia may have begun in 1730 BCE.[67] In ancient China, though, glassmaking seems to have a late start, compared to ceramics and metal work. The term glass developed in the late Roman Empire. It was in the Roman glassmakingcenter at Trier, now in modern Germany, that the late-Latin term glesum originated, probably from a Germanic word for atransparent, lustrous substance.[68] Glass objects have been recovered across the Roman Empire[69] in domestic, funerary,[70]and industrial contexts.[71] Examples ofRoman glass have been found outside of the former Roman Empire in China,[72] the Baltics, the Middle East and India.[73]

Glass was used extensively during the Middle Ages. Anglo-Saxon glass has been found across England during archaeological excavations of both settlement and cemetery sites.[74] Glass in the Anglo-Saxon period was used in the manufacture of a range of objects including vessels, windows,[75] beads,[76] and was also used in jewelry.[77] From the 10th-century onwards, glass was employed instained glass windows of churches andcathedrals, with famous examples at Chartres Cathedral and the Basilica of Saint Denis. By the 14th-century, architects were designing buildings with walls of stained glass such asSainte-Chapelle, Paris, (1203–1248)[78] and the East end of Gloucester Cathedral.[79]Stained glass had a major revival with Gothic Revival architecture in the 19th century.[80]With the Renaissance, and a change in architectural style, the use of large stained glass windows became less prevalent.[81] The use of domestic stained glass increased[82]until most substantial houses had glass windows. These were initially small panes leaded together, but with the changes in technology, glass could be manufactured relatively cheaply in increasingly larger sheets. This led to larger window panes, and, in the 20th-century, to much larger windows in ordinary domestic and commercial buildings.

In the 20th century, new types of glass such as laminated glass, reinforced glass and glass bricks[83] increased the use of glass as a building material and resulted in new applications of glass.[84] Multi-story buildings are frequently constructed with curtain wallsmade almost entirely of glass.[85] Similarly, laminated glass has been widely applied to vehicles for windscreens.[86] Optical glass for spectacles has been used since the Middle Ages.[87] The production of lenses has become increasingly proficient, aiding astronomers[88] as well as having other application in medicine and science.[89] Glass is also employed as the aperture cover in many solar energy collectors.[90]

From the 19th century, there was a revival in many ancient glass-making techniques including cameo glass, achieved for the first time since the Roman Empire and initially mostly used for pieces in a neo-classicalstyle.[91] The Art Nouveau movement made great use of glass,[92] with René Lalique, Émile Gallé, and Daum of Nancy producing colored vases and similar pieces, often in cameo glass, and also using luster techniques. Louis Comfort Tiffany in America specialized in stained glass, both secular and religious, and his famous lamps. The early 20th-century saw the large-scale factory production of glass art by firms such as Waterford and Lalique. From about 1960 onwards, there have been an increasing number of small studios hand-producing glass artworks, and glass artists began to class themselves as in effect sculptors working in glass, and their works as part fine arts.

In the 21st century, scientists observe the properties of ancient stained glass windows, in which suspended nanoparticles prevent UV light from causing chemical reactions that change image colors, are developing photographic techniques that use similar stained glass to capture true color images ofMars for the 2019 ESA Mars Rover mission.[93]

Chronology of advances in architectural glass

- 1226: "Broad Sheet" first produced inSussex.[94]

- 1330: "Crown glass" for art work and vessels first produced in Rouen, France.[95]"Broad Sheet" also produced. Both were also supplied for export.

- 1500s: A method of making mirrors out of plate glass was developed by Venetian glassmakers on the island of Murano, who covered the back of the glass with a mercury-tin amalgam, obtaining near-perfect and undistorted reflection.

- 1620s: "Blown plate" first produced in London.[96] Used for mirrors and coach plates.[97]

- 1678: "Crown glass" first produced in London.[98] This process dominated until the 19th century.

- 1843: An early form of "float glass" invented by Henry Bessemer, pouring glass onto liquid tin. Expensive and not a commercial success.

- 1874: Tempered glass is developed by Francois Barthelemy Alfred Royer de la Bastie (1830–1901) of Paris, France by quenching almost molten glass in a heated bath of oil or grease.

- 1888: Machine-rolled glass introduced, allowing patterns.[99]

- 1898: Wired-cast glass first commercially produced by Pilkington[100] for use where safety or security was an issue.[101]

- 1959: Float glass launched in UK. Invented by Sir Alastair Pilkington.[102][103]

Comments

Post a Comment